Marking Techniques

There are a number of marking techniques that can produce the desired result. Each technique has its own set of characteristics that will influence the optimum choice for your marking requirements. Click on the technique listed in the menu at the top of the page to find the best option for your particular needs or contact JBR and we will guide you to the proper marking technique.

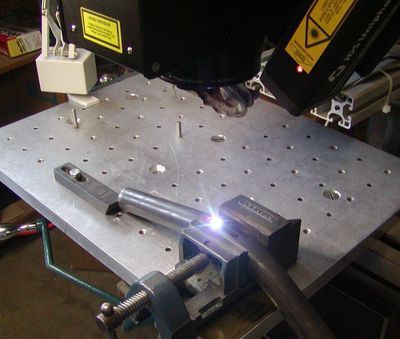

- Laser Marking & Engraving - JBR uses advanced fiber lasers (20 to 50 watts) to produce high-contrast, durable markings such as part numbers, serializations, barcodes, and logos. This process is ideal for medical and dental components due to its ability to withstand sterilization and autoclaving.

- Screen Printing (Silk Screening) - An economical solution for printing on metals and plastics, screen printing is used for everything from single-color identification to multi-color branding and graphic applications.

- Mechanical Engraving - Traditional rotary engraving offers deep, permanent markings ideal for industrial applications on rigid surfaces.

- Pad Printing - This method allows for precise imprinting on irregular or contoured surfaces, often used in branding and part identification.